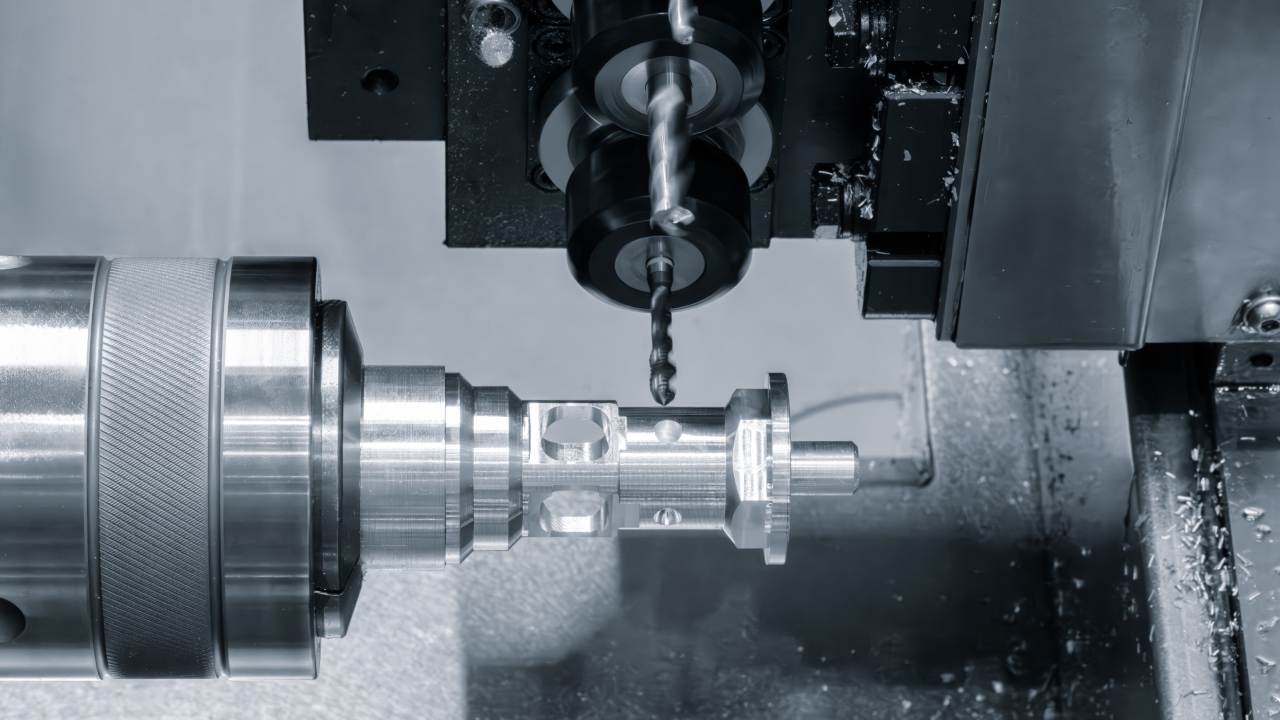

A boring mill, technically referred to as a boring machine, is engineered to enlarge holes that have previously been drilled or cast. These machines are the backbone of the heavy industry sector, primarily utilized in metalworking to achieve precise diameters and superior finishes. They are particularly vital for machining heavy components and larger workpieces where accuracy is non-negotiable.

The logistics involved in transporting a boring machine can be intricate due to their sheer size and weight. However, Atlantic Project Cargo is dedicated to solving these challenges. We provide dependable, cost-efficient transport services designed to ensure the safe, timely delivery of your valuable equipment. Request your free quote today!

Modes of Boring Machine Transportation Services Offered by Atlantic Project Cargo

Ground

For domestic relocation or short-haul international shipments, our company delivers reliable ground transport services. This includes:

- Truckload shipping: Dedicated transport for your machine tool

- Flatbed transportation: Ideal for general machinery

- Specialized equipment: Trailers designed for heavy components and oversized loads

Ocean

For long-distance global deliveries, Atlantic Project Cargo provides efficient ocean freight solutions:

- Roll-on/Roll-off (RoRo) shipping: Efficient for mobile machinery

- Containerized shipping: For smaller, disassembled parts like the boring bar or headstock

- Breakbulk shipping: The standard for shipping massive boring machines that cannot be containerized

Air

When speed is the critical factor, we offer rapid air freight services:

- Air charters: Exclusive aircraft for urgent industrial needs

- Commercial airline cargo: Expedited shipping via standard routes

Get Your Free Quote Today!

How to Ship Heavy Equipment via Ocean Freight?

Why Choose Atlantic Project Cargo For Boring Mill Shipping?

Get your free quote today if you are seeking reliable industrial equipment delivery services!

How Much Does it Cost to Ship Boring Machines?

Mode of transportation: Air charters command a higher price point compared to ocean or ground transportation options

Distance: Moving a boring machine across the country is generally more economical than transporting it overseas

Additional expenses: These may include insurance premiums, special permits, customs duties, and energy surcharges

Size and Weight: The heavier the machinery and the larger the dimensions, the higher the shipping expense

Season: The shipping industry experiences high and low seasons, which directly impact the final cost

International Shipping of Boring Mills

Roll-on-Roll-off (Ro-Ro)

This is a streamlined method of shipping where machinery is driven or towed directly onto and off the vessel

Full-Container Load (FCL)

This implies that the entire container is exclusively reserved for your shipment. It is a favored choice for shipping precision equipment components to ensure they stay dry and secure

Flat Rack

An excellent choice for transporting machines, particularly those that are oversized or have dimensions exceeding standard container limits

Air Cargo

The most rapid method for shipping a boring mill or its critical parts, though it comes at a higher cost

International Shipping Compliance, Regulations, and Restrictions for Boring Mills

Regulations vary significantly by nation, but the most common requirements include:

- Export control: Adherence to ITAR, EAR, and similar frameworks

- Import regulations: Payment of tariffs & duties, adherence to non-tariff barriers, safety standards, and customs clearance procedures

- Transport regulations: Accurate shipping documentation, dangerous goods protocols, weight and dimensions restrictions, and insurance mandates

- Technical standards: Variances in safety standards, emissions, and noise regulations

Boring Machine Moving Services Across The Country

Flatbed

These trailers provide a foundational, open platform for securing and hauling boring mills efficiently

Step-Deck

Featuring a lowered rear platform, this trailer type offers the necessary clearance to transport machinery legally without necessitating special height permits

RGN (Removable Gooseneck)

The most significant benefit of RGN trailers is their capacity to accommodate high loads and extremely heavy production equipment

Restrictions on Moving Boring Mills

Moving equipment over extended distances involves various restrictions and regulations, including:

- Road regulations: Adherence to speed limits, width and height restrictions, and road use permits

- Transport regulations: Requirements for oversized load permits, escort vehicles, precise route planning, and liability insurance

- Additional regulations: Seasonal travel restrictions, weight limits per axle, and specific local municipal regulations

Google Reviews

Frequently Asked Questions

Yes, we provide extensive heavy machinery shipping services both domestically and internationally. We serve various industries, ensuring your planer or boring mill reaches its destination safely.

The total transit time is contingent upon the distance, the selected shipping method, and any potential delays. We provide precise estimated delivery times during the quote process so you can plan your operations accordingly.

Absolutely. We offer comprehensive insurance coverage to protect your machinery during transit. Given the tightest tolerances these machines operate under, financial protection against damage is essential.

Documentation requirements fluctuate based on the shipping destination. Typically, you will need a bill of lading, a commercial invoice, and potentially export/import permits. Our team includes experts who can assist you with compiling the necessary documentation.

Yes, we offer complete door-to-door pickup and delivery services for your convenience. We can collect the unit from your facility and deliver it to the new location, whether it’s an older model or a modern CNC unit.

For larger workpieces of machinery, partial disassembly is often required to meet road height and weight regulations. We can assist in planning the removal of the headstock, spindle, or tooling to ensure the load is safe and legal.

We utilize air-ride trailers and specialized blocking and bracing techniques. This minimizes vibration and shock, which is critical for maintaining the high precision and reliability that boring machines are known for.