The commodity supply chain (CSC) is a complex system. It involves multiple parties and processes to bring demanding goods to market. Understanding the CSC is crucial for businesses, retailers, and distributors, as it affects everything from pricing and availability to economic growth.

In this article, we will give the definition of the commodity chain, reveal its stages, and explain the differences between the upstream and downstream chains. We will look at the strategies to improve the CSC and the most effective commodity chain examples.

Shipping goods is an essential part of the CSC. Our freight forwarding company Atlantic Project Cargo may help you with this. We offer top-quality domestic cargo transportation, and import and export services, including insurance, customs brokerage, ensuring necessary documentation, requirements compliance, and more.

What is the Commodity Supply Chain?

The main focus of the CSC is the transformation of source materials into finished goods and moving them to consumers efficiently and effectively.

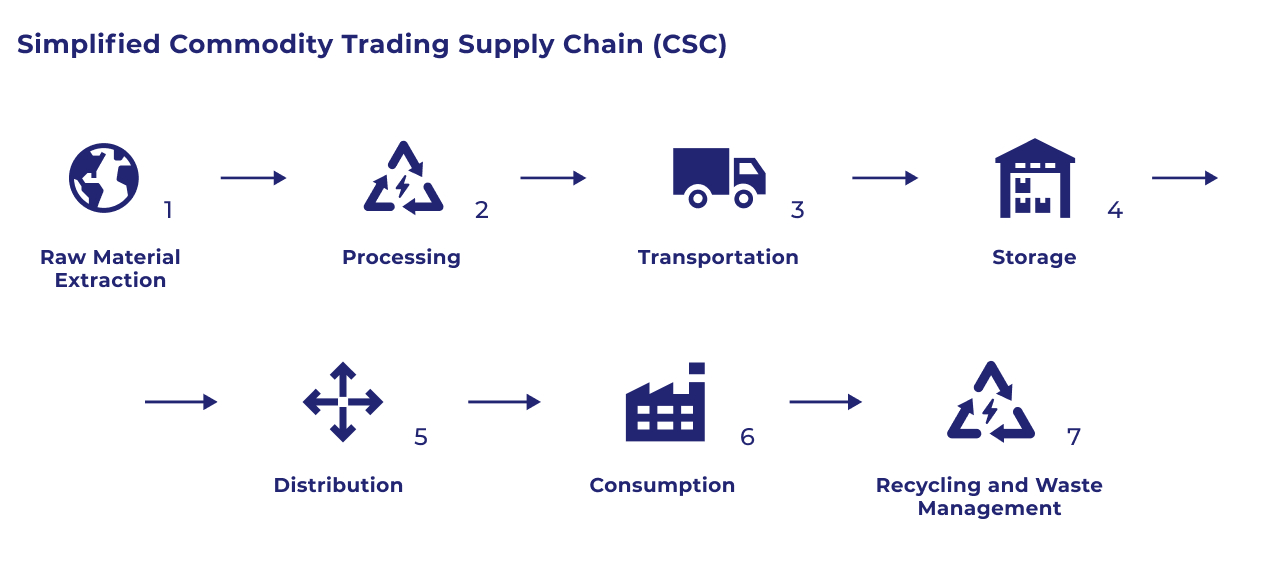

The CSC includes several stages, each critical to ensuring that commodities are delivered from producers to end users:

- Raw Material Extraction

The initial stage where natural resources are extracted. This includes mining minerals, drilling for oil, or harvesting agricultural products - Processing

The materials are converted into usable forms. For example, crude oil is refined into gasoline, and wheat is milled into flour - Transportation

Goods are transported from production sites to markets. This can involve various modes of transport, e.g. trucks, ships, trains, and pipelines - Storage

Some products need storage facilities to hold them before sale. This is especially important for perishable goods or seasonal crops - Distribution

The goods are distributed to wholesalers, retailers, or directly to consumers. This stage involves logistics and supply chain management - Consumption

Finally, goods reach the end user. They can be another business or a final buyer - Recycling and Waste Management*

In some cases, the chain includes the used materials return for recycling or disposal

Each component of the CSC adds not only value to the final product but also costs.

These stages can be divided into two groups:

- Upstream (extraction of materials and production of goods)

- Downstream (storage and transportation of finished goods)

It should be noted that the oil and gas industry consists of three segments: upstream, midstream, and downstream. Here midstream chain links upstream and downstream through the collection, transportation, and storage of energy products.

The chains can be unique depending on market or product types. They may include different economic sectors or be handled by the same business.

Upstream vs. Downstream Supply Chain

What is an Upstream Supply Chain?

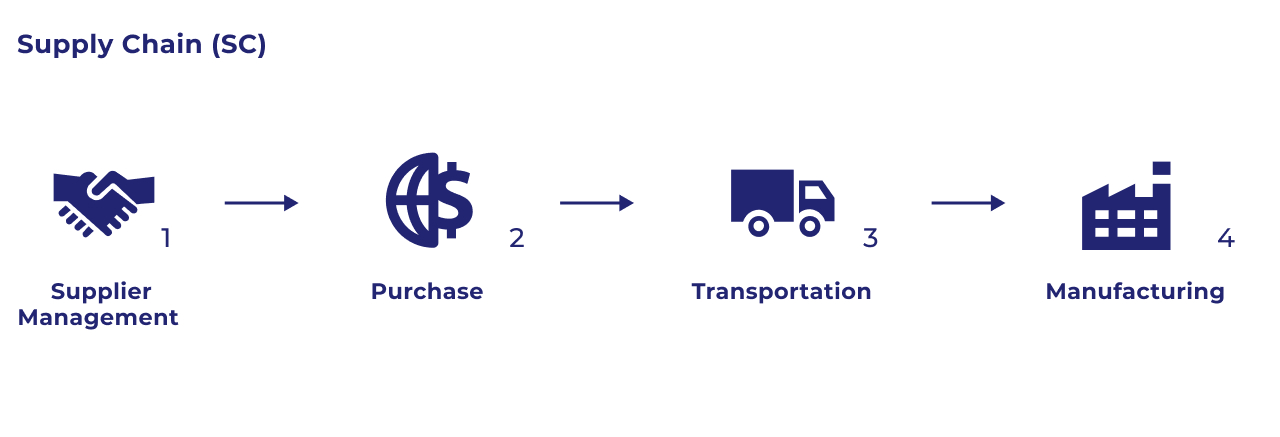

Upstream operations are the first steps in the supply chain. Here companies find and transport source materials to manufacturers and then produce goods.

The main upstream operations:

- Supplier Management

Building good relationships with trustworthy suppliers who can deliver high-quality materials at fair prices - Purchase

Buying the raw materials needed, ensuring they meet the required quality standards - Transportation

Movement of materials to manufacturing sites, with a focus on making sure deliveries are on time - Manufacturing

Raw materials go through different modifications and become finished goods

What is a Downstream Supply Chain?

The main downstream operations:

- Warehousing

Storing and managing products so they are ready to be sent out when needed - Marketing and sales

The activities like advertising campaigns and sales strategies promote the product and facilitate its sales - Order Management

Processing customer orders efficiently, keeping track of inventory, and coordinating how orders are fulfilled - Distribution of goods

Delivery of products to customers

Key Differences Between Upstream and Downstream SCs

Although upstream and downstream operations are parts of the same SC, they have some key differences.

Focus

The upstream SC involves getting raw materials and production. So this mainly aims to reduce costs and improve efficiency, while saving product quality.

Downstream operations focus on marketing, storing, and delivering the final product. That is why their efforts prioritize shipping speed and customer satisfaction.

Flow of Materials and Information

The upstream SC is all about the movement of materials. This includes getting them and managing the manufacturing process. A continuous flow of materials is essential for keeping production and delivery on time.

In contrast, the downstream SC focuses more on the flow of information. This involves tracking inventory and delivery, managing customer orders, and creating marketing plans.

Timing and Responsiveness

The upstream SC is centered around when to buy materials and when to produce items. The goal is to ensure that materials arrive just when needed to avoid delays. Poor timing can lead to running out of stock or having too much inventory.

Being responsive is key for the downstream SC. This means how well a company can adjust to changes in customer needs and market conditions.

Supplier and Customer Relationships

Building a network of suppliers is important for the upstream SC. This greatly affects production efficiency, material costs, and overall profitability.

The downstream SC is more focused on customers. It involves getting the finished product to market and ensuring customer satisfaction through distribution, marketing, sales, and support after the sale.

Risk and Inventory Management

In the upstream SC, the focus is on managing risks like supply failures, price changes, quality issues, or disruptions from events like natural disasters.

The downstream SC deals with managing the storage and movement of products. This includes predicting demand, deciding how much inventory to keep, coordinating with distribution centers, and handling logistics.

Strategies to Improve the Commodity Supply Chain

Here are three important strategies that can help improve SC operations, both upstream and downstream.

Visibility

Visibility means the ability to see and keep track of products, materials, and information movement. It includes collecting information about the amount of inventory, production process, and goods transportation and distribution.

There are some advantages to see what is going on in the SC:

- Issues Prevention

It helps you spot potential problems before they happen. You can easily identify obstacles and keep your SC running smoothly - Higher Flexibility

Having better visibility makes you adapt and make quick changes to boost productivity, regardless of the circumstances - Quick Decision Making

The necessary actual data allows you to make better decisions - Meet Growing Customer Demand

Full visibility helps you understand how to meet customer needs precisely

Intelligence

SC intelligence means using data analysis tools and technologies. It includes gathering and examining information from different sources, like partners, customers, or special software. By using insights from this data, companies can find new ways to save money, work better, and grow.

The key components in SC intelligence:

- Data Collection

This information can include stock levels, order updates, and shipment tracking - Data Integration

Bringing information from various sources and systems to a complete picture of the process - Analytics and Reporting

This is necessary for understanding how well the SC is working and to find any slow spots or problems - Risk Management

Up-to-date information on potential problems helps reduce risks like shortages or delivery delays

Collaboration

Collaboration means communication and teamwork among everyone in the SC.

Effective cooperation requires trust, transparency, and goal consistency between all parties. Collaboration can lead to faster decision-making, improved usage of resources, and better productivity.

Below are some advantages of cooperation in the SC:

- Reliable supply assurance

Constant high inventory levels lead to increased profits, fewer penalties, and faster deliveries - Greater efficiency

Synchronizing operations and sharing ideas optimize all the processes involved - Higher resilience and agility

Creating collaborative and responsive processes minimizes the impact of unforeseen events, and ensures continuity of operations - Improved product quality

Rapid exchange of inspection data, notifications, and other information helps to identify quality problems early and ensure that each product meets standards - Responsiveness to demand changes

Joint forecasting and planning makes it possible to meet real market requirements to optimize stocks and avoid shortages

Most Effective Commodity Chain Examples

There is a list of the top 5 companies that have successful and effective SC management.

Intel

This leading global technology manufacturer prioritizes market needs and supply demands. Intel has improved its competitiveness through real-time analytics. This approach simplifies its SCs and adopts predictive analytics for manufacturing.

As a result, Intel has achieved a return on investment of $208 million within five years.

Amazon

It is one of the largest online retailers thanks to Amazon Global Selling. Their strategies keep inventory levels low while ensuring fast delivery. With Amazon Prime, some customers can receive deliveries in under two hours.

Amazon enhanced customer satisfaction even further. They developed the Prime Air. This drone delivery service moves packages within thirty minutes of placing an order.

Zara

Zara’s waste management strategy addresses many aspects of the SC. The company aims to minimize environmental impact while ensuring efficiency and cost-effectiveness.

In logistics, Zara’s vehicles use biodiesel. The production processes focus on organic cotton and eco-friendly fabrics. Innovative technology allows for precise cutting, measuring, and handling of materials to reduce waste.

Coca-Cola

The company manages every aspect of its product creation, marketing, and distribution worldwide. The strategy of this well-known brand goes beyond simple distribution.

The company segments its markets to enhance its appeal. That is why flavors, concentrations, sizes, and packaging can vary by region. 95% of the drinks are produced in the countries where they are sold, maximizing efficiency.

Unilever

This company produces a wide range of products, including food, beverages, cleaning agents, beauty, and cosmetics. Despite this, Unilever effectively manages multiple SCs.

Unilever uses a combination of centralized and decentralized models. It allows the company to adapt its operations to local markets.

Also, the company uses AI actively. This tool helps identify alternative ingredients that can enhance sustainability, and make formulations more sustainable and cost-effective.

Conclusion

The CSC connects entrepreneurs across the globe. By learning how it works they can better understand the challenges that come with it. Staying informed about the CSC’s dynamics is essential for successful business development.

If you need safe and effective cargo transportation, whether these are source materials or finished products, Atlantic Project Cargo will help you. Our experts will ensure an effective and successful journey for your goods.

Read More