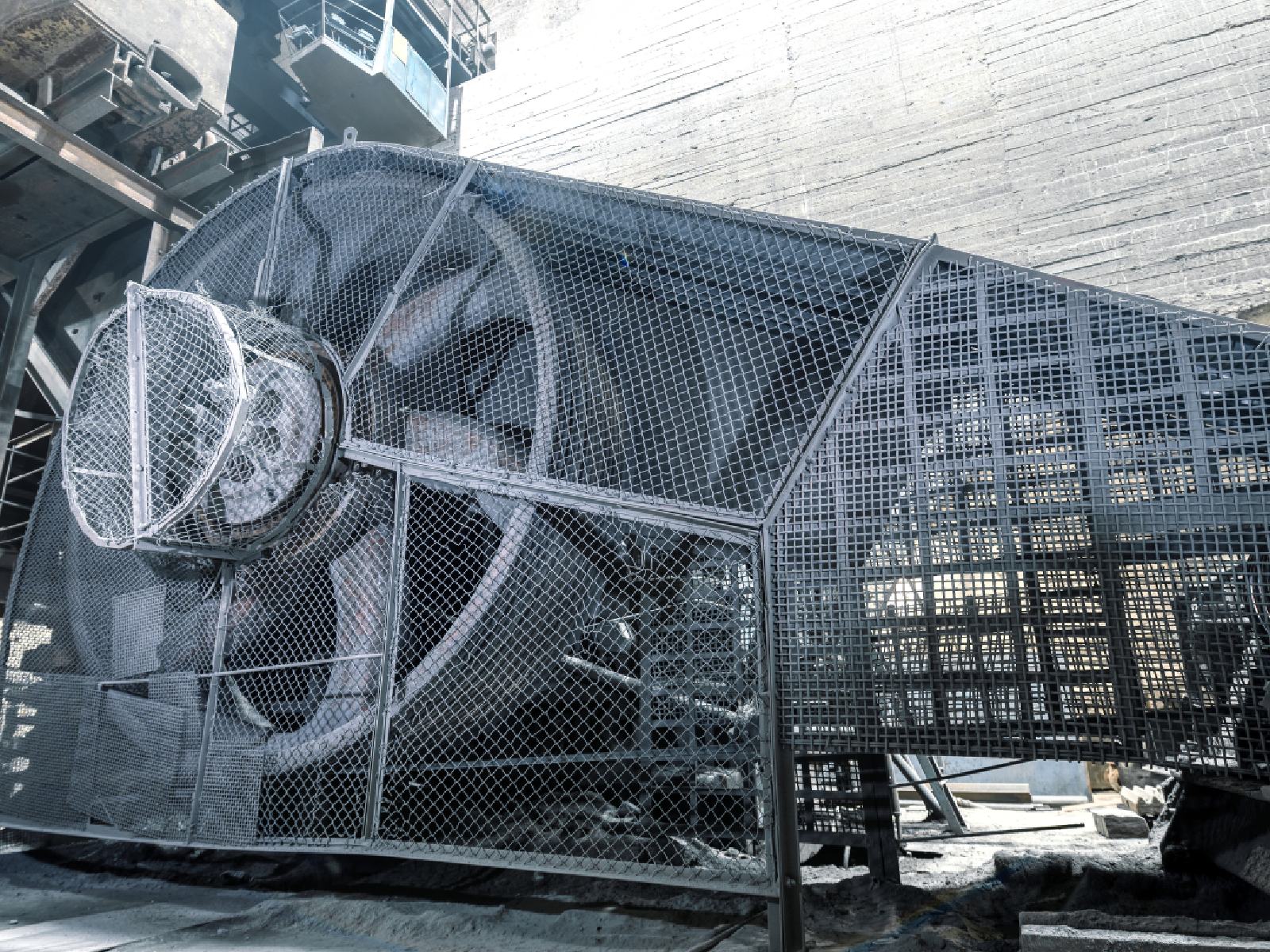

A rock crusher is a piece of heavy machinery that crushes large rocks into smaller ones. This equipment is commonly used in the mining, industrial, and construction industries.

Transporting industrial rock crushers can be challenging, but Atlantic Project Cargo is here to help. We offer reliable and cost-effective solutions to ensure safe and timely delivery of your equipment! Get your free quote today!

Modes of Rock Crusher Transportation Services Offered by Atlantic Project Cargo

Ground

Our company’s reliable ground transport services cover domestic and short-haul international shipments. This includes:

- Truckload shipping

- Flatbed transportation

- Specialized equipment

Ocean

Efficient ocean freight solutions for long-distance deliveries are provided by Atlantic Project Cargo:

- Roll-on/Roll-off (RoRo) shipping

- Containerized shipping

- Breakbulk shipping

Air

Rapid air freight services are available for when time is of the essence:

- Air charters

- Commercial airline cargo

Get Your Free Quote Today!

How to Ship Rock Crushers via Ocean Freight?

Why Choose Atlantic Project Cargo For Rock Crusher Shipping?

Get your free quote today, if you are looking for rock crusher delivery services!

How Much Does it Cost to Ship Rock Crushers?

Transport method: Air freight is the most expensive option compared to ocean or ground

Distance: Transporting rock crushers domestically will be less expensive than shipping it internationally

Associated fees: This includes costs like insurance, permits, customs duties, and other charges

Dimensions and weight: The cost increases with the rock crusher’s weight and size

Seasonality: The final price is impacted by fluctuations between high and low shipping seasons

International Shipping of Rock Crushers

Roll-on-Roll-off (Ro-Ro)

In this shipping method, a rock crusher is driven directly onto the ship and then driven off at the destination

Full-Container Load (FCL)

Your rock crusher shipment gets an entire container to itself. This is a common choice for shipping equipment because of the security and control it provides

Flat Rack

This is an excellent option for shipping cargo, particularly for rock crushers that are oversized or have dimensions that exceed a standard container’s limits

Air Cargo

Although it is a high-cost option, this is the fastest method for transporting machinery or its components

International Shipping Compliance, Regulations, and Restrictions for Rock Crushers

While country-specific rules vary, the most common regulations include:

- Export control (ITAR, EAR, and so on)

- Import regulations (tariffs & duties, non-tariff barriers, safety standards, customs clearance)

- Transport regulations (shipping documentation, dangerous goods regulations, weight and dimensions restrictions, insurance and others)

- Technical standards (differences in safety standards, emissions, and noise regulations)

- Phytosanitary certificates (required for machinery if it interacts with the ground and is transported to Australia or New Zealand)

Rock Crusher Moving Services Across The Country

Flatbed

These trailers offer a basic, open platform for securing and rock crusher hauling

Step-Deck

Lowered rear platform, provides the necessary clearance to transport machinery legally without requiring special permits

RGN

Their key advantage is the ability to haul exceptionally high and heavy loads

Restrictions on Moving Rock Crushers

Moving equipment over long distances comes with restrictions and regulations, such as:

- Road regulations (speed limits, width and height restrictions, road use permits)

- Transport regulations (oversized load permits, escort vehicles, route planning, insurance)

- Additional regulations (seasonal restrictions, weight limits, local regulations)

Google Reviews

Frequently Asked Questions

Yes. We offer both domestic and international shipping services for all types of construction equipment and heavy duty machines. We are specialists in transporting rock crushers, including rock crushing equipment setups, mobile crushers for on site crushing, and large-scale machines for mining operations.

The delivery time for a crusher depends on the distance, transport method (ground, ocean, or air), and specific route. Shipping portable rock crushers to a domestic job site will be much faster than transporting a massive primary gyratory crusher overseas. We provide accurate transit time estimates during the quote process to help you plan your operations.

Yes, we provide comprehensive insurance coverage to protect your high-value equipment during transit. A rock crusher machine, whether it’s a primary jaw crusher or a sophisticated cone crusher, is a major investment. Our policies cover your machine from pickup to delivery, ensuring your assets are protected.

The required documents vary by destination. For international shipments of rock crushing equipment, you will typically need a bill of lading, a commercial invoice, and potentially export/import permits. Our expert team assists with all necessary documentation to ensure your crusher (whether for rock, ore, concrete, or gravel) clears customs without delays.

Yes, we provide full door-to-door pickup and delivery services. We can coordinate the logistics to move your crushers directly from a manufacturer, auction, or active mining job site. We handle all the complexities, including disassembly and reassembly coordination for stationary equipment or transport for mobile crushers.

A rock crusher machine is a piece of heavy equipment designed for size reduction — its purpose is to crush large rocks into smaller pieces, gravel, sand, or a desired size for further processing. This crushing action typically happens in multiple crushing stages:

- Primary crushing: This is the first stage of rock crushing. Large materials and raw materials (like ore or blasted rock) are fed into a primary crusher. The most common types are jaw crushers and gyratory crushers.

- A jaw crusher uses compressive force from two jaws — a fixed jaw and a movable jaw. An eccentric shaft drives the movable jaw (often via a toggle plate), creating the crushing action inside the crushing chamber.

- A gyratory crusher breaks rock by squeezing it between an oscillating main shaft and a concave bowl liner (the outer crushing surfaces).

- Secondary and tertiary crushing: The crushed material from the primary stage, now smaller rocks, is moved by conveyor belt to secondary and tertiary crushing stages for further size reduction.

- Cone crushers are very common for secondary and tertiary crushing. They are similar to gyratory crushers but have a less steep chamber, making them suitable for producing high quality aggregates.

- Impact crushers (like HSI crushers or VSI crushers) use high-speed impact rather than compression. They are excellent for fine crushing and are often used in the final stages (even quaternary crushing) to shape materials like sand or concrete aggregates, often at a lower cost per ton.